Wear-resistant Rubber Sheet

- Advanced rubber process, strong comprehensive performance, the leader products of wear – resistant materials

- Effective protection, prolong the service life of equipment

- Softkill, wear reduction, voice reduction

- Free cutting and collocation, flexible application

- Independent research and development, special bonding agents, firm bonding

Advanced production technology, the performance with the world's leading standard

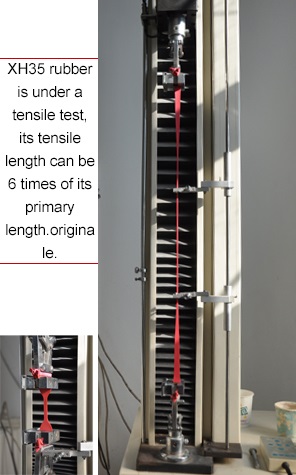

Creative technology reserves the molecular chain of natural rubber.The content of natural rubber reaches 95%; uniform rubber vulcanization, strong comprehensive performance

Tests show that Xinhai Wear - resistant Rubber sheet owns excellent performance:

Wear resistance index 128%

Resilience 80%

Tensile strength 23.5MP

Tearing strength 168N/mm

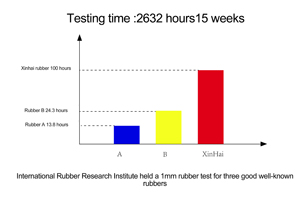

High wear resistance and corrosion resistance, 1 mm per hour wear records

The wear resistance index of Xinhai Wear – resistant Rubber sheetreaches 128%

1 mm wear experiment shows that Xinhai Wear – resistant Rubber which takes 100 hours to wear 1 mm wins out over the other kinds of rubber which takes 13.8 hour and 24 hour respectively to wear 1 mm.

The excellent wear – resistant performance effectively prolongs the rubber service life.

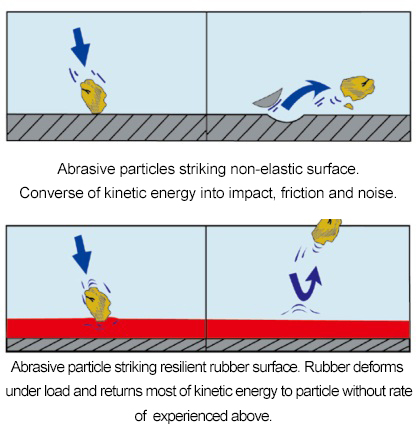

Wear – resistant rubber sheet, excellent elasticity, consumption reduction, voice reduction

Wear – resistant rubber sheet, excellent elasticity, consumption reduction, voice reduction

Xinhai Wear – resistant rubber with high elasticity is different from the hard materials such as cast stone, compounding ceramics, alloy, iron, etc. It can effectively absorb and repulse the impact and friction force,which takesthe loss to a minimum, the noise to the lowest, showing the characteristics of softkill.

Flexible and convenient cutting, wide application

Flexible and convenient cutting, wide application

Cutting and bonding the wear – resistant rubber to meet various shape and surface requirements, according to the need of piping, pipe fittings, hopper, chute, cylinder, and so on.

Special bonding agents, firm bonding

Xinhai Bonding Agents developedaiming to mining machinery are applied to bonding metals, leathers, plastics, fabrics, timbers, and so on. The bonding agents has many advantages, such as high bonding strength, high resilience, resistance to impact, vibration, water, acid, alkali, ageing, etc.

Product FAQ

How to bond rubber with rubber?

Scrub the rubber surface with cotton cloth dipped in prepared active agent

Apply the prepared rubber cement on rubber surface and dry in the air (10~15 minutes)

Apply the cement again on the rubber surface after drying the first level cement, coincide the bonding surface when it is not sticky

Because bonding surface is stuck in a short time, adjust position before pressing, and insure no deviation. Press the surface then with rubber hammer or pressing roll in order to force the air out.

How to classify wear rubber?

According to whether to clip medium, rubber is divided into pure gum rubber and cloth, metal frame layer folder plastic sheet and other varieties.

According to using, rubber is divided into industrial rubber plate and rubber flooring.

According to the physical and chemical properties, rubber is divided intocloth sandwiched rubber sheet,cloth-stick rubber sheet, insulation rubber sheet,oil proof rubber sheet、acid and alkali resistant rubber sheet, etc.

According to the color and surface treatment, rubber can be divided into: black rubber sheet, green rubber sheet, red rubber sheet,white rubber sheet, yellow rubber sheet, blue rubber sheet, grey rubber sheet, embossed rubber sheet, super wide rubber sheet, etc.

Product parameter

|

Rubber types |

XinHai35 |

XinHai40 |

XinHai50 |

XinHai60 |

XinHai HD62 |

XinHai HD70 |

XinHai HDS |

XinHai BB |

XinHai N55 |

XinHai OZ |

XinHai FG |

|

Color |

Red |

Red |

Red |

Red |

Black |

Black |

Red |

Black |

Orange |

Black |

White |

|

Polymer type |

Nature |

Nature |

Nature |

Nature |

Nature |

Nature |

Nature |

halogenating Neoprene |

Synthetic rubber |

Pure nature rubber |

Nature |

|

hardness |

35 |

39 |

50 |

60 |

62 |

70 |

70 |

55 |

55 |

38 |

38 |

|

Tensile strength |

23.5 |

25 |

29 |

28 |

22 |

23 |

22.8 |

10.0 |

19 |

26.7 |

25.9 |

|

Elongation at break |

866% |

750% |

750% |

750% |

700% |

600% |

580% |

580% |

740% |

760% |

810% |

|

Tension set |

4% |

6% |

20% |

40% |

12% |

14% |

25% |

15% |

12% |

10% |

7% |

|

Tear strength |

81.34 |

80 |

140 |

168 |

136 |

142 |

100 |

40 |

71 |

40 |

52 |

|

Resilience |

76% |

74% |

68% |

56% |

50% |

44% |

57% |

|

34% |

83% |

82% |

|

Specific gravity |

0.95 |

0.95 |

1.06 |

1.1 |

1.12 |

1.14 |

1.14 |

1.42 |

1.14 |

0.98 |

1.01 |

|

Temperature range |

-40~70 |

-40~70 |

-40~70 |

-40~75 |

-40~75 |

-40~75 |

-40~75 |

-40~120 |

-20~110 |

-40~75 |

-40~70 |

|

Wear resistance index |

≥128% |

≥90% |

≥40% |

≥20% |

≥40% |

≥40% |

≥38% |

|

≥16% |

|

|

Related products

Copyright: Xinhai material technology company

You must indicate the author and primitive source and this statement with links when reprinting