Better rubber liner, higher efficiency of ball mill

By:Xinhai

2018-05-25 | Browse the number (5681)

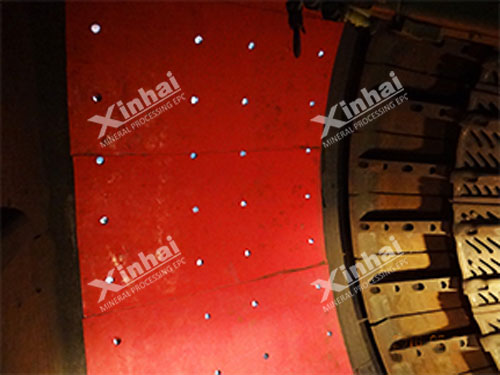

Compared to the traditional alloy plate, rubber liner of ball mill is more popularized by its unique advantages. Generally, alloy plate has a lot of problems, such as long time-consuming, complicated installation, replacement difficulties, etc., besides, its wearing resistance is not as good as the rubber liner. Finally, rubber liner is widely applied in many mineral processing plants for its small density, easy to processing and strong wear-resisting.

However, not all ball mill rubber lining boards are featured with strong wear-resisting performance like Xinhai super wear-resisting rubber liner. As the only one wet natural wear-resisting rubber manufacturer in China, Xinhai makes the content of natural rubber reaches 95%. In addition, Xinhai has passed the appraisal of Xinhai wet rubber production wear-resisting key technology and industrialization from National Technical Committee of Science and Technology, which is about the special liquid nano formulations—room temperature curing.

Now, Xinhai wear-resistant rubber plays a leading role in the international mineral processing plant. Xinhai not only used it in rubber liner of ball mill, but also in wear-resistant rubber pump, high wear-resistant hydrocyclone, screen, valve and other rubber product, which can stick to any metal in a cold way and effectively solve the wear problems in the mineral processing plant. Generally, Xinhai wear-resistant rubber can increase 10% working efficiency of equipment.

As the first mineral processing EPC service provider who expanded its business overseas, Xinhai brings its mineral processing technology and grinding equipment to more than 90 countries and regions. What’s more, Xinhai wear-resistant rubber is inspected by international trade inspection, and passed the ISO9011: 2008 and CE and other international quality management system certification.

So far, Xinhai wear-resistant rubber liner of ball mill liner gets extensive praise from international peers, which proves the success of its ball mill rubber liner.