Tailings Dry Stacking

Using the tailings pool to stack tailings is out of time. Tailings pool not only requires huge tracts of land, but also brings hidden danger of the dam break and mud-rock flow. It also brings pollution to the surrounding waters, air and other natural environment. The tailings cannot be effectively reused, neither safe, nor environmental protection, which do not meet the national sustainable development policy. The Tailing Dry Stacking has become a new generation method to disposal tailings.

Advantages of Tailings dry stacking:

1. The tailings of the dry storage do not need to occupy large tracts of land or build massive tailings.

2. Water resources can return to factory to reuse, which saves money.

3. Dry tailings can be used for brick making and damming achieving reutilization

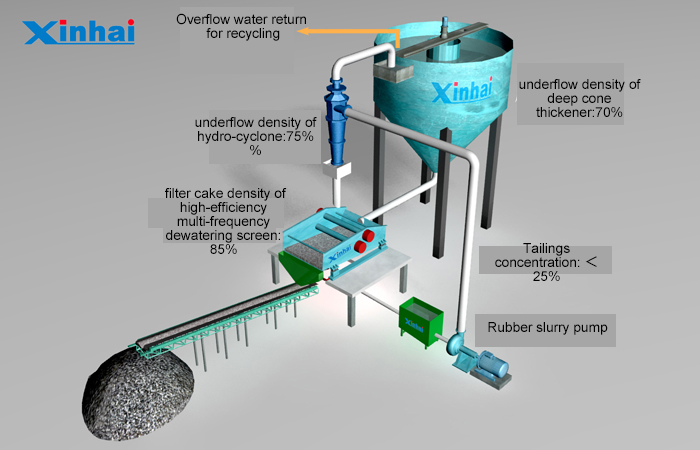

Flow sheet of Xinhai Tailing dry stacking system

Yantai Xinhai initiatively developed Xinhai Tailing dry stacking system relying on mineral processing experience for 20 years and strong technical strength, and spread this system in tailing disposal which was successful. At present, Xinhai is the company which undertake tailings dry stacking project most.

Advantages of Xinhai tailings dry stacking system

Equipment investment is saved 30-50% with operation cost less than 2 yuan /t

Xinhai developed concentrated hydrocyclone with underflow concentration up to about 75%, which reduce the equipment investment of tailings dry stacking follow – up need, and save 30-50% than other tailings disposal process.

This system with hook – ups equipment is easy to operate and manage without high requirement of workers in quantity and technology. The operation cost is less than 2 yuan/t

Energy saving, saving 2kw.h/t

In Xinhai tailings dry stacking system, the hydrocyclone is no power consumption. Xinhai wear-resistant slurry pump is the rubber pump that power consumption is about 30% lower than the other pump.

The power consumption of Efficient Multi – frequency Dewatering Screen is less than Filter Press. The whole system is very energy-saving about 2kw.h/t.

Deep and multi cone thickener

Conservation of water resources, the return rate up to 85%

The equipment of Xinhai Tailing Dry Stacking System all has the thickening and dewatering function. Taking Deep and multi cone thickener for an example, it improves the concentration efficiency by the design of deep and multi cone. The underflow concentration can reach 70% when the overflow of the hydraulic cyclone goes through the thickener. According to the different nature of the tailings, dewatering rate and the return rate is different, and the highest rate up to 85%.

Efficient Multi – frequency Dewatering Screen

Wear – resistant rubber as equipment liners, long service life

Xinhai Slurry Pump, Hydraulic Cyclone, and Efficient Multi – frequency Dewatering Screen all use Xinhai Wear – resistant rubber as liners or components, such as impeller of slurry pump, wet parts of hydrocyclone, absorber of dewatering screen, etc. The wear – resistant rubber protects the equipment which prolongs the use life and reduces repair frequency.

Cases

As the first domestic company for tailings dry stacking, our company has completed nearly 100 projects

Welcome to visit our tailings dry stacking of mineral processing production line. Online consulting more cases

|

|

|

|