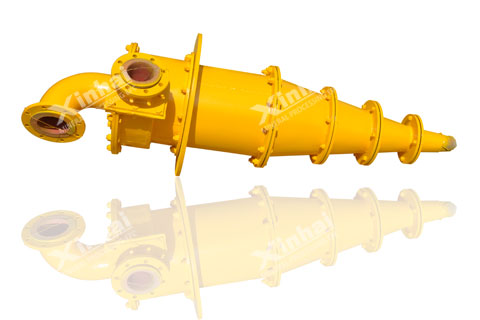

Hydrocyclone

- Wear – resistant rubber as liners, double prolong the service life of equipment

- New design of feed port, eliminating the disturbance, reduce wear and improve the classification efficiency of 85%

- Reasonable cyclone structure design, less phenomenon of overflow with coarse particles

- Adjust underflow concentration according to the needing

High wear-resistant rubber wet parts, protection of internal flow, strong stability

Xinhai hydrocyclone is lined with Xinhai 35 wear – resistant rubber which owns super wear resistance, resilience and strength to prolong the service life of cyclone.

Meanwhile it can help your cyclone to keep dimension and shape of the internal flowing tube, so as to keep to stable classifying efficiency.

Unique involute feeding port design, the classification efficiency increased to 85%

The way of involute feeding through the inlet branch reduces the turbulence of the burst emanative flow when materials entry, makes a smooth movement of liquid inside cyclone, therefore gives a sharp classification.

The internal flow passage without sharp edges and corners can ensure the slurry flow smoothly in the internal and reduce wear. In the practical application, the comprehensive efficiency is increased to about 85%.

The rational length proportion of column and cone and reasonable insert depth of vortex finder, reduce overflow with coarse particles

The length proportion of column and cone and insert depth of vortex finder improves the classification efficiency of cyclone. The special structure of vortex finder and cone structure reduces the overflow with coarse particle and underflow with fine particle.

The unique design can control the concentration of overflow and underflow according to needing.

Special design 1: Siphoning Installation

The siphoning installation above the overflow box can adjust the concentration of the underflow up to 60%. The overflow discharge is almost clear water and can reduce the overall energy consumption pressure 1/3

Special design 2: fishtail

The special designed fishtail at spigot can maintain a constant underflow discharge density and overflow fineness despite variations in feed volume, feed density and feed pressure in a certain range.

Note: Xinhai owns professional selection soft of cyclone to fulfill the customers needing.

Product FAQ

Inlet pressure how to effect the classification of hydrocyclone

入Inlet pressure is an important parameter of hydrocyclone work. Improving the inlet pressure can increase the pulp flow and centrifugal force, so it improves the classification efficiency and underflow concentration. But increasing the pressure to reduce the size grading has little effect, energy consumption has increased significantly, and the cyclone underflow mouth wears more seriously. The low pressure(0.05 ~ 0.1MPa) treatment for raw material operation, high pressure (0.1 ~ 0.3MPa) for fine and argillaceous materials operation

Feed volume how to effect the classification of hydrocyclone?

Increasing the feeding volume, particle size becomes big; reducing the feeding volume, particle size becomes small.

Ore feeding concentration how to effect the overflow and underflow?

The needing of cyclone feeding concentration depends on the specific material. The feeding concentration is high the same with underflow and overflow concentration. The feeding concentration is low, and the underflow concentration will be reduced accordingly which reduces the overflow with coarse particle. In conclusion concentration neither higher nor lower is better.

Product parameter

|

Cyclone specs |

Capacity |

Cut size |

Vortex finder dia. |

Spigot dia. |

Inlet pressure |

|

150 |

10-23 |

25-74 |

30-50 |

8-22 |

0.060-0.15 |

|

200 |

17-38 |

28-80 |

40-65 |

16-32 |

0.060-0.15 |

|

250 |

24-53 |

30-82 |

65-100 |

16-40 |

0.060-0.15 |

|

300 |

40-100 |

36-90 |

65-120 |

20-40 |

0.060-0.15 |

|

350 |

56-118 |

40-100 |

80-120 |

30-70 |

0.060-0.15 |

|

375 |

74-157 |

42-105 |

90-135 |

30-70 |

0.060-0.15 |

|

450 |

90-192 |

44-110 |

100-150 |

30-70 |

0.060-0.15 |

|

500 |

128-300 |

50-115 |

130-220 |

35-100 |

0.060-0.15 |

|

610 |

200-468 |

57-125 |

160-260 |

65-110 |

0.060-0.15 |

|

660 |

237-524 |

60-130 |

180-280 |

80-150 |

0.060-0.15 |

Related products

Copyright: Xinhai material technology company

You must indicate the author and primitive source and this statement with links when reprinting