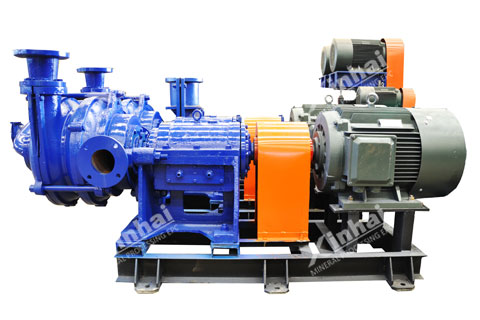

High head slurry pump

- Double stages rubber slurry pump, resistance to wear and corrosion, high head

- Double stages design, break through the head limit (50 meters) of rubber pump, up to 70 meters

- Wear – resistant wet parts, excellent protection to pump body, prolong the service life, reduce the maintenance cost of 60%

- Small specific gravity of rubber impeller, improve rotation speed, reduce consumption of 30%

- High resilience of rubber liners, 100% sealing and no leakage

An ideal feeding pump of filterResistance to wear and corrosion, high head

High head slurry pump with 35 wear –resistant rubber liners which excellently protect the body of pump breaks through the head record 50 m. The rubber slurry pump with resistance to wear and corrosion and high head is especially suitable for feeding to filters.

Double stages design, head up to 70 m

Double impellers serial design without increasing the diameter of the impeller makes head up to 70 meters, which is the head of the rubber pump.

Wear – resistant rubber liners prolong the service life of pump and reduce the faults.

Impellers and casings lined with Xinhai No. 35 high wear-resisting rubber, the life is 1 times longer than the life of metal pump.

Due to the resilience of wear – resistant rubber, the pump with low faults rate resists the impact and wear. It is easy and convenient to replace the liners, so the overall maintenance cost is reduced by 60%

Rubber liners with small specific gravity, the first choice of energy saving equipment

The specific gravity of rubber liners and impellers is smaller than metal’s (wear – resistant rubber is 0.97; metal is 7.87). The power of rubber liners is smaller too. The overall consumption reduces by 30%.

High resilience rubber liners, 100% no blockage

Xinhai high head slurry pump with packing seal uses high elastic rubber liner to enhance the sealing performance. In practice, no leakage occurs; sealing method is simple and convenient to manage.

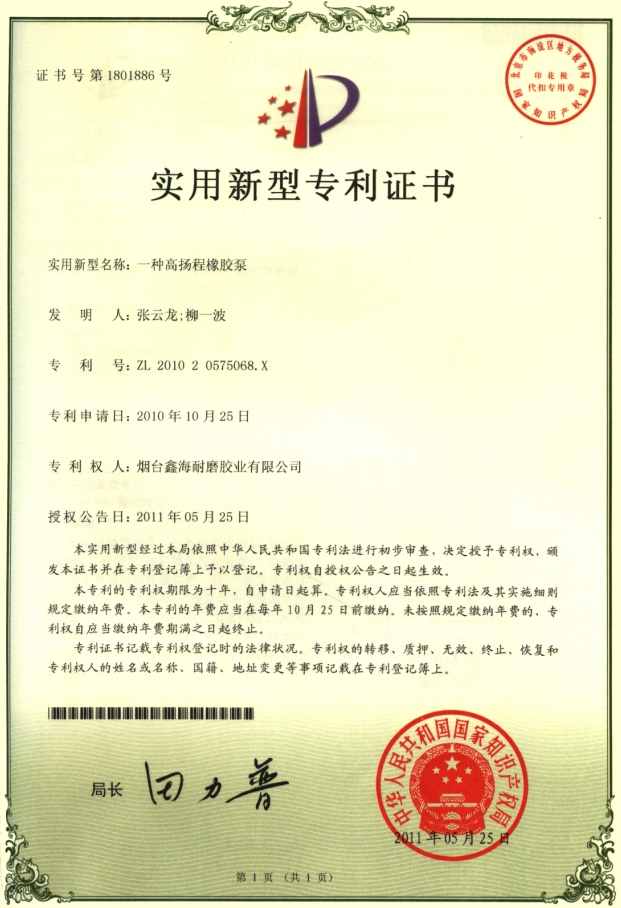

Xinhai high head slurry pump applies the utility model patent, patent No. ZL 2010 2 0575068.X.

High performance price ratio of high head slurry pump

|

High head slurry pump |

traditional slurry pump |

|

Excellent energy saving performance30% |

High energy consumption |

|

Reduce noise by60%,Efficiency increased by20% |

Noise, low efficiency |

|

Wear – resistant rubber as liners, prolong service life1times |

short service life |

|

liners protection, simple maintenance, save manpower and time |

Repair installation is time-consuming and laborious, spent a lot of manpower |

|

The overall performance price ratio beyond170% |

High cost |

Warm tips:

The application of high head slurry pump

Slurry flow:60~120h/m2

Slurry concentration:<60%

Temperature range:-40℃~70℃

Product FAQ

How to maintain the high head slurry pump?

1、The bearing pressure and water volume to meet the requirements, adjust (or replace)the tightness of packing, pay attention to shaft leakage and timely replace sleeve

2、 The replacement of bearings, must guarantee that the bearing assembly is clean. The temperature of bearings between 60℃ and 65℃

3、Timely replacement easily damaged parts, correct maintenance assembly, reasonable gap adjustment, avoid friction phenomenon.

4、 if the downtime of the equipment is long, user should wash the pump before restart the pump.

5、To ensure the concentricity of motor and pump, ensure elastic cushion of the coupling is complete and correct, timely replace the damaged parts

6、Ensure that the pump components and piping system is installed correctly, firmly and reliably.

Why is the insulation resistance of motor winding lower than 0.5 megohm?

1、Magnet wire winding becomes aging or damaged, users should unpack the winding, use self-adhesive tape bandage to pack breakage or rewind the new coil.

2、Rubber cable breakage, users should find the breakage and use self-adhesive tape bandage to repack breakage.

3、Sealing joint invalid, users should unpack, connect, and rewrap.

The reason of slurry pumps shaft seal leakage?

1、Without shaft seal water or seal water pressure is not enough, users should timely add shaft seal water or increase the pressure of shaft seal water

2、Packing is too loose or incorrect installation, users should adjust the packing.

3、The sleeve of serious wear, replace the new sleeve timely

Product parameter

|

Item |

Rotation |

Flow |

Head |

Max shaft power |

Referenced motor(KW) |

|

|

Model |

Power |

|||||

|

XPA(2)-50 |

1480 |

27.5 |

76.0 |

22.3 |

Y225S-4 |

37 |

|

41.4 |

72.2 |

|||||

|

55.2 |

66.1 |

|||||

|

69.0 |

56.0 |

|||||

|

80.0 |

43.5 |

|||||

|

XPA(2)-65 |

1480 |

40.0 |

76.0 |

32 |

Y225M-4 |

45 |

|

60.0 |

72.2 |

|||||

|

80.0 |

66.1 |

|||||

|

100.0 |

56.0 |

|||||

|

115.0 |

43.5 |

|||||

|

XPA(2)-75 |

1480 |

56.0 |

73.3 |

49 |

Y250M-4 |

55 |

|

85.0 |

69.0 |

|||||

|

113 |

62.5 |

|||||

|

150 |

51.2 |

|||||

|

169 |

44.0 |

|||||

|

XPA(2)-100 |

1480 |

70.0 |

73.5 |

62.5 |

Y280S-4 |

75 |

|

105 |

71.6 |

|||||

|

140 |

68.6 |

|||||

|

186 |

61.9 |

|||||

|

245 |

48.5 |

|||||

|

XPA(2)-100-Ⅰ |

1480 |

79.7 |

80.0 |

78.2 |

Y280M-4 |

90 |

|

119 |

78.0 |

|||||

|

159 |

74.8 |

|||||

|

211 |

67.5 |

|||||

|

279 |

52.9 |

|||||

|

XPA(2)-100-Ⅱ |

1480 |

58.0 |

91.8 |

64.7 |

Y280M-4 |

90 |

|

87.0 |

89.1 |

|||||

|

116 |

85.7 |

|||||

|

154 |

77.3 |

|||||

|

203 |

60.6 |

|||||

Related products

Copyright: Xinhai material technology company

You must indicate the author and primitive source and this statement with links when reprinting

Guest book

News

Hot

Related articles

- Wear – resistant rubber slurry pump PK alloy slurry pump

- The wear – resistant slurry pump how to break through 50 m head?

- Reasonable selection of slurry pump

- Reduction of cavitations erosion and wear ----- Xinhai wear – resistant slurry pump

- Practicability of Wear – resistant Slurry Pump

- How to solve wear problem of slurry pump?