Pinch valve

- Rubber liners, high resilience, guarantee sealing, no leakage

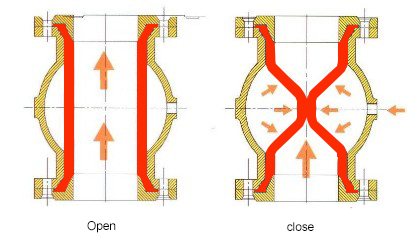

- New design section, reasonable structure, no blocking

- Wear - resistant rubber spool, high resilience, reliable opening and closing

- Wear – resistant rubber liners, resistance to corrosion and wear, prolong the service life of equipment 2 times

High resilience rubber liners with rubber boss, no leakage

Xinhai wear – resistant rubber is called “the king of rubber” with high wear resistance and resilience.

Flange interface also lined with rubber does not need any sealing device, where is closely connection and strong sealing.

No internal flow resistance, no blockage

Smooth internal surface makes slurry flow stably and fast without flow resistance. In practical application, never be blocking.

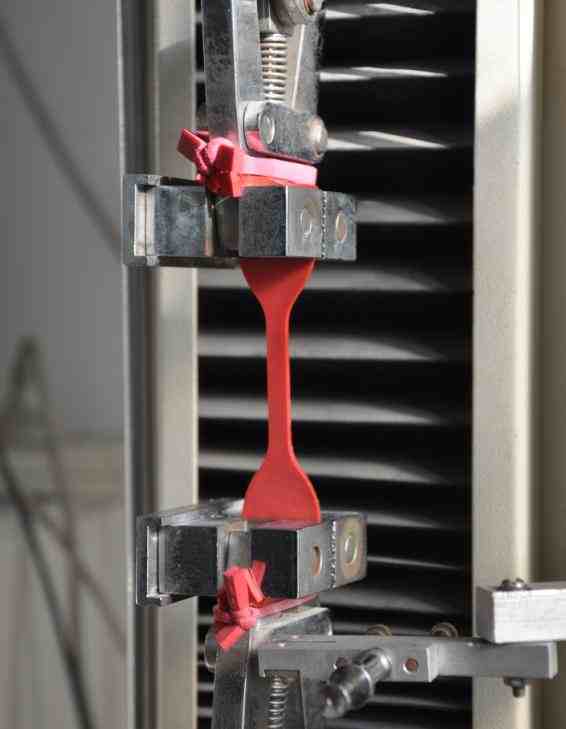

High resilience rubber spool, more flexible and reliable opening and closing

The spools are rubber hose made of wear – resistant rubber with high resilience. Hand brake compresses bushing to control the closing and opening.

Note: Quick opening and closing reduces the damage of hose.

Wear – resistant rubber spools, quality guaranteed

The spools of Xinhai pinch valve are made of wear – resistant rubber with high resistance to wear and corrosion which prolongs the service life of equipment.

Far beyond the polyurethane usage, Xinhai rubber excellent wear resistance reduces the damage rate and the maintenance cost about 60%.

Product FAQ

Which fields dose the pinch valve applied to?

Wear and non – wear pipelines

Uniform addition of reagents in chemical industry or mine

Uniform ore drawing in mineral processing technology

What are the disadvantages of pinch valve?

The valve is mainly used in low pressure environment, generally less than PN 16.

Rubber casing is the core of the pinch valve, so the using temperature has limitation, usually between -20~65 ℃.

Limited by rubber process, the caliber of pipe valve usually is within DN 300 mm in order to meet the quality of casing strength. Large caliber pinch valves bring higher prices.

Warm tips:

Pay attention to the following items when you use Xinhai pinch valve:

Not recommended for negative pressure

Not recommended for severe throttling duties

The bushings are designed for pressure up to 10.5KG/cm2. If the required pressure is higher than the limitation pressure, please contact with us.

Product parameter

|

Spec |

D |

B |

C |

A |

E |

F |

G |

Standard flange |

Weight (kg) |

|||

|

Flange dia |

Bolt PCD |

Bolt dia |

Aluminum |

Cast iron |

||||||||

|

20 |

20 |

144 |

150 |

15 |

119 |

80 |

100 |

105 |

75 |

4-Φ14 |

1.6 |

2.8 |

|

25 |

25 |

159 |

165 |

15 |

119 |

90 |

125 |

115 |

85 |

4-Φ14 |

2.3 |

3.2 |

|

40 |

40 |

199 |

205 |

17 |

119 |

118 |

162 |

140 |

100 |

4-Φ18 |

3.5 |

5.5 |

|

50 |

50 |

229 |

235 |

17 |

220 |

156 |

185 |

150 |

110 |

4-Φ18 |

6.5 |

12.5 |

|

65 |

65 |

299 |

305 |

17 |

220 |

190 |

200 |

165 |

125 |

4-Φ18 |

8.8 |

15 |

|

80 |

80 |

309 |

315 |

21 |

220 |

202 |

225 |

185 |

145 |

4-Φ18 |

10.5 |

22 |

|

100 |

100 |

354 |

360 |

25 |

220 |

247 |

269.5 |

200 |

160 |

8-Φ18 |

18.2 |

41 |

|

125 |

125 |

419 |

425 |

28 |

280 |

310 |

350 |

220 |

180 |

8-Φ18 |

29 |

66 |

|

150 |

150 |

479 |

485 |

29 |

280 |

343 |

373 |

285 |

240 |

8-Φ18 |

42 |

99 |

|

200 |

200 |

594 |

600 |

30 |

280 |

457 |

486.5 |

340 |

295 |

8-Φ22 |

87 |

230 |

Related products

Copyright: Xinhai material technology company

You must indicate the author and primitive source and this statement with links when reprinting