Rubber process

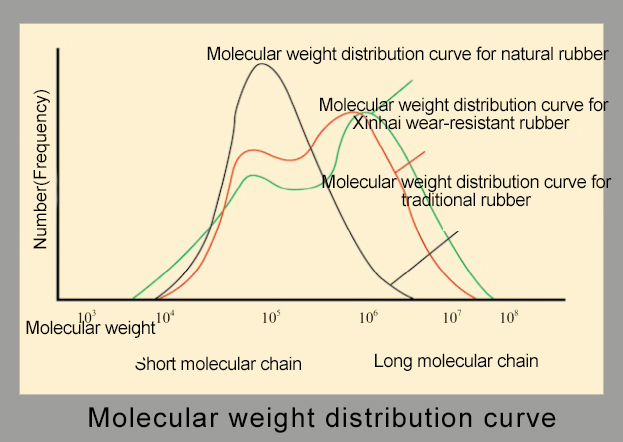

The wear resistance of rubber products depends on the nature rubber content and molecular chain integrity. Therefore, the wear resistance can be strengthened by keeping high content of the nature rubber and reducing the damage of the molecular chain.

Yantai Xinhai Wear–resistant Rubber Company successfully developed the technology named Liquid phase nanometer compounding•normal temperature high–frequency curing after continued efforts which broke more than 80 years’ monopoly in rubber field by a foreign company. The rubber products of Xinhai are called the King of the Rubber. In wet environment, some performances are second of none in China and also at the head of the world, such as wear resistance, resilience, tearing strength, etc.

Rubber technology breakthrough, the domestic initiative, the only----Liquid phase nanometer compounding•normal temperature high – frequency curing

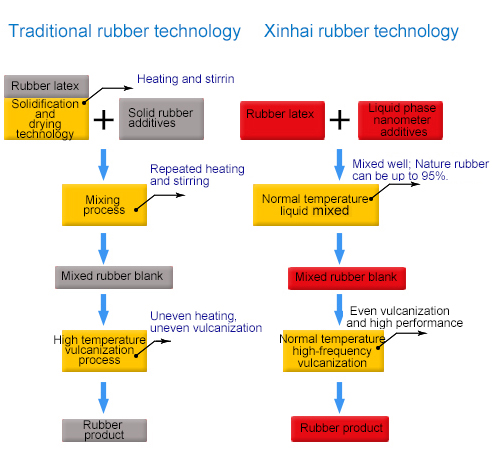

Rubber technologies comparison

Xinhai wear– resistant rubber

Normal rubber

Xinhai Wear–resistant Rubber ---- the King of the Rubber

Liquid phase process, rubber quality guarantee

Xinhai Wet Rubber Process reduces the damage of natural rubber molecular chain and reserve the natural wear resistance during productive process.

Comparison with different kinds of rubber by instruments as shown in the figure, the molecular chain of traditional rubber was destroyed. The content of long molecular chain is small except for short molecular chain.

But the Xinhai Wear-resistant rubber molecular curve closest to natural rubber molecules curve, the maximally keep the abrasion resistance of natural rubber molecules.

Patent nano–addictives, high grade rubber guarantee

Additives with nanometer, more easily penetrate into the latex, mixed more evenly. Therefore, only very few additives, ensure the content of natural rubber in the maintained at a higher level. This allows the natural wear resistance of rubber to be reserved.

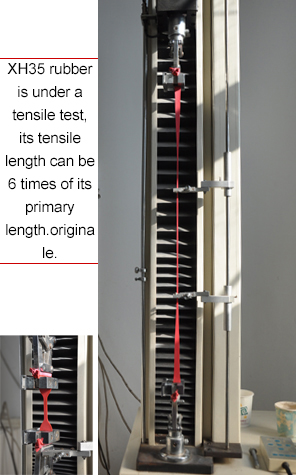

- 0.25mm rubber strip of Xinhai Wear–resistant rubber is not out of shape until is stretched to 800%

- The resilience of Xinhai Wear–resistant rubber reaches 80%

- The tensile strength of Xinhai Wear–resistant rubber reaches 23.5MP

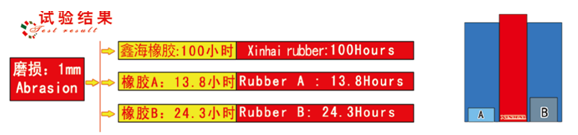

International Rubber Research Institute tests three kinds of high quality rubber generally recognized by the accelerated wear experiment. Test time is 2632 hours (15 weeks). The experiments show that the Xinhai wear– resistant rubber is much better than other wear–resistant rubber in wear resistance.

Normal temperature and high frequency vulcanization, excellence performance guarantee

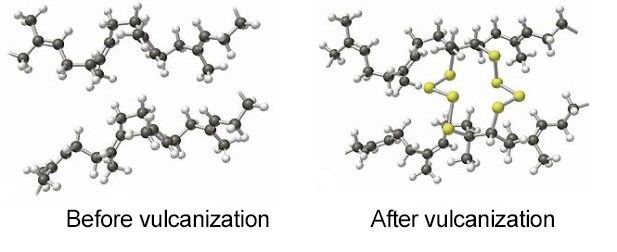

Vulcanization is that the linear molecules build "Sulfur Bridge" between each other forming the three-dimensional network structure in a certain temperature by adding a certain amount of vulcanizater to the semi product made of raw rubber, so as to increase the elasticity of the rubber.

Traditional heating mode is very difficult to ensure that the rubber blank is heated evenly, especially for large size products, its external heating is far more than the internal heat, resulting in external rubber "more sulfur", while the internal rubber "less sulfur". Uneven vulcanization seriously affects the overall performance of rubber products.

The interior and exterior of rubber is heated at the same time and vulcanized synchronously shortening the time of the vulcanization by Xinhai normal temperature and high frequency vulcanization adopting high frequency induction heating technology. The quality of vulcanization is better, and the wear resistance of rubber is more outstanding.

Related data standard formula rubber comparison table that Xinhai wear-resistant rubber compares with some well-known international brands and national contrast detection

|

Rubber types |

XH35 Rubber |

national standard rubber |

some international brand rubber |

|

|

Color |

red, yellow |

black |

red |

|

| Polymer type |

Natural |

Natural |

Natural |

|

|

Performance Parameter |

Testing standard |

|

|

|

|

Hardness Shore (A) |

GB/T 6031-1998 |

35 |

65 |

38 |

|

Tensile strength (Mpa) |

GB/T 528-1998 |

23.5 |

26.52 |

23.3 |

|

Elongation at break (%) |

GB/T 6031-1998 |

866 |

426.8 |

768 |

|

Tension set (%) |

GB/T 528-1998 |

4 |

28 |

6 |

|

Tearing strength (N/mm) |

GB/T 529-1998 |

81.34 |

164.32 |

70.44 |

|

Resilience % |

GB/T 1681-1991 |

76 |

45 |

74 |

|

Specific gravity (g/cm3) |

|

0.95 |

1.1272 |

0.97 |

|

Wear resistance index (%) |

GB/T 9867-1988 |

128 |

10.8 |

100 |

Note: the date is gotten referring to hardness of 38 of the international brand rubber under wet-type condition.

Considerate and excellent rubber products

With decades experience in mine production, Xinhai group perfectly combines the wear – resistant rubber with mineral processing equipment aiming at every wear process, and develops many patent and efficient wear – resistant machinery.

Xinhai wear–resistant equipment with wear–resistant rubber as liners which have wear and tear resistance, prolongs the service life and save energy reaching the world leading level.

Guest book

News

Xinhai material technology company Products Rubber processing News Tailings dry stacking Website map

Business license number:鲁ICP备05051618号 Copyright © 2006-2026 YANTAI XINHAI MATERIALS TECHNOLOGY CO., LTD; Service hotline:0086 13810327080