Alloy Slurry Pump

- Advanced two phase flow design (solid & liquid), head reaching 125 m

- Diversified sealing designs are available according to different working conditions

- Multi-stage in serious, TDH reaching 1000m

- Double choices of rubber/alloy wet parts

Large flow, high rotation speed, 125m head, wide application

With solid & liquid two phase flow design, the head reaches 125m. With special inner design, it does not suffer from mash interference and no block. The flow rate is 20% higher than ordinary slurry pumps and can be applied to many conditions.

Four sealing styles, free collocation, free replacement

Xinhai Alloy slurry pump could adopt four sealing styles that every style owns its own advantages. They ensure stable performance and no leakage. Clients could choose them according to the actual condition.

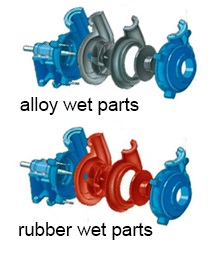

Free collocation of rubber and alloy wet parts, enhancing the service

Double choices of high-chromium alloy and wear-resistant liners, one ensures high head, the other ensures super wear resistance.

Moreover, clients can combine the two advantages together to improve comprehensive efficiency and prolong the service life.

Multi-stage in series

Alloy slurry pumps improve the head by adopting multistage series. The maximum head reaches 1000m. Clients could require the number of stages according to their needs.

Product FAQ

Why do not the alloy slurry pumps absorb slurry?

1, Reason: Impeller is damaged Solution: replace a new impeller

2, Reason: suction pipe blocked Solution: unclog the pipe

What are the reasons that lead to slurry pump power being too high?

1. Reason: the filler is too much and too much pressure on the cover Solution: loose the gland bold

2. Reason: there is friction in pump Solution: adjust the gap

3. Reason: bearing is damaged Solution: change bearing

4. Reason: pump flow is too large Solution: adjust the pump’s operation

What are the reasons that slurry pump bearing life is short?

1, Reason: Motor shaft and pump shaft are asymmetry or nonparallel Solution: Adjust the concentricity of the Motor shaft and pump shaft

2, Reason: there is friction in pump or impeller imbalance Solution: Eliminate friction, replace impeller or find the balance

3, Reason: there is impurity in bearing resulting in a long time friction. Solution: wash bearing

4, Reason: unreasonable bearing assembly Solution: reassemble bearing

What are the reasons that slurry pump cause big noise?

1, Reason: bearing is damaged Solution: replace bearing

2, Reason: impeller imbalance Solution: find the balance or replace new impeller

3, Reason: suction pipe blocking Solution: remove air, clean the pipe

4, Reason: uneven flow, pump depletion Solution: improve pump feeding condition

Product parameter

|

Specs |

40×pc |

50×pc |

80×pc |

100×pc |

150×pc |

200×pc |

250×pc |

300×pc |

Related products

Copyright: Xinhai material technology company

You must indicate the author and primitive source and this statement with links when reprinting

Guest book

News

Hot

Related articles

- Wear – resistant rubber slurry pump PK alloy slurry pump

- The wear – resistant slurry pump how to break through 50 m head?

- Reasonable selection of slurry pump

- Reduction of cavitations erosion and wear ----- Xinhai wear – resistant slurry pump

- Practicability of Wear – resistant Slurry Pump

- How to solve wear problem of slurry pump?